Why the U.S. Faces a Shortage of Skilled Garment Makers & Why a Skilled Labor Shortage Demands Innovative Solutions

- Brittney Cunningham

- Aug 12

- 5 min read

Updated: Aug 14

The Looming Crisis in U.S. Garment Manufacturing

The U.S. garment industry is at a tipping point. While conversations about American manufacturing often focus on semiconductors or steel, one of the most acute shortages is hiding in plain sight: highly skilled garment makers. The American garment industry, once a global powerhouse, is currently grappling with a significant and growing shortage of skilled garment makers. This deficit, particularly acute in the high-end and couture sectors, presents a major obstacle to industry growth, long-term viability, and the imperative to bring manufacturing back to the United States.

In particular, luxury tailoring and couture-level garment construction are in short supply—a reality that threatens not only the future of American fashion but also the nation’s ability to bring production home. For decades, offshoring promised cost savings. But with global supply chain disruptions, rising tariffs on imported apparel, and growing consumer demand for sustainability and local production, the industry is waking up to an urgent truth:

Without skilled workers, you can’t reshore fashion.

How We Got Here: Offshoring and the Erosion of Skills

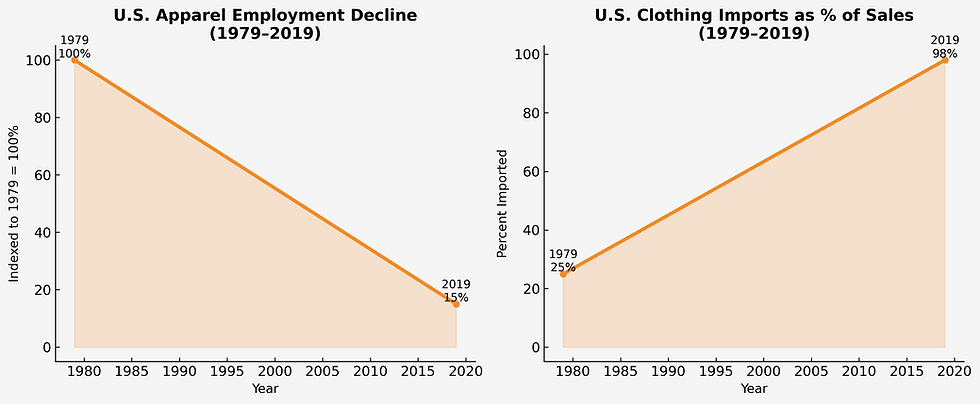

The U.S. apparel industry has been in steady decline for decades. Employment in the apparel and textile industries plummeted by over 85% between 1979 and 2019, as U.S. apparel brands chased lower labor costs overseas. The result was a gradual hollowing out of domestic expertise. Today, over 98% of the clothing sold in the United States is imported, a stark reversal from a time when a significant portion of our apparel was made domestically.

As generations of tailors, patternmakers, and couture seamstresses retired, their skills were not passed on. The work had moved offshore, and garment making was no longer perceived as a viable, long-term career path for young people. This erosion of skills has left a critical void, transforming what was once a robust industry into a fragmented landscape of a few remaining artisans and small-scale operations. Without robust apprenticeship programs or a clear training pipeline, we have lost not just jobs, but the artistry and precision that are the hallmarks of high-end garment production.

The Talent Pipeline Problem

The shortage is not just about numbers; it's about craftsmanship. Luxury garment making is a specialized skill set that takes years to master, but the industry has done little to actively recruit and train new talent. This challenge is magnified by an aging workforce. With the median age of manufacturing workers at 44.5 years—and a significant portion of the workforce nearing retirement—the skills gap widens with each passing year.

The demand for domestic production is climbing, yet our bench of highly skilled workers is shrinking. This has left the industry without the talent needed to meet the growing need for high-end, customized, and sustainable garments.

Tariffs, Reshoring, and the Pressure to Adapt

Recent tariff hikes on imported apparel, particularly on goods from major producers like China and Vietnam, are pushing brands to reconsider domestic manufacturing. While reshoring offers a solution to supply chain headaches and geopolitical risks, it is a complex and challenging endeavor. Tariffs, while incentivizing domestic production, also raise the cost of imported fabrics and components that U.S. manufacturers still rely on, creating a complicated dynamic.

Simultaneously, sustainability-minded consumers are driving new demand for alterations, custom work, and garment repairs. This "slow fashion" movement is creating a new market for skilled tailors—if we can find them. The rising cost of imported fast fashion, due in part to tariffs, makes extending the life of garments through repair and customization an increasingly attractive and necessary option for consumers.

Enter Seamsdress: Building the Missing Link

Seamsdress is tackling this shortage head-on by rebuilding the bridge between brands, customers, and skilled makers. The company’s comprehensive approach provides the tools and infrastructure needed for a domestic manufacturing renaissance.

The Seamsdress Directory:

A curated, searchable network of luxury garment professionals. Whether a designer needs a master tailor for a bespoke menswear line or a fashion brand requires an experienced seamstress for intricate bridal alterations, Seamsdress makes it easy to connect with the right talent.

A Marketplace + Workflow Hub

Seamsdress is a complete marketplace, bidding, and workflow hub for the garment industry. Customers and brands can submit alteration requests, custom clothing designs, or bulk production needs, and skilled tailors and manufacturers can bid on these projects. Every job is managed end-to-end—from booking and secure payment to real-time tracking—all within a single platform.

2. Mentorship and Apprenticeship Opportunities: By pairing emerging artisans with seasoned professionals, Seamsdress is reviving the tradition of skill transfer. This model is essential for creating the next generation of couture-level talent and ensuring that valuable knowledge is not lost.

3. Data-Driven Talent Development: An integrated Data Operating System tracks skills, career progression, and industry demand. This allows manufacturers to identify talent gaps early, design targeted training, and ensure a steady pipeline of qualified workers. This proactive approach helps the industry anticipate future needs rather than react to crises.

4. AI-Enhanced On-Demand Tailoring: From customizations to repairs, Seamsdress uses AI-driven tools to make alterations more accessible, efficient, and cost-effective. This extends the life of garments, reduces waste, and directly supports the sustainability goals that are increasingly important to modern consumers.

Smarter Sizing, Seamless Fit: The AI-Powered Revolution

The shortage of skilled labor is only one half of the fashion industry's problem. The other is the persistent issue of sizing inconsistencies, which leads to an estimated 30-40% return rate for online clothing, with a significant portion due to poor fit. This not only creates logistical headaches for brands but also generates massive textile waste. Seamsdress is tackling this problem head-on with an AI-powered data platform that benefits both consumers and producers.

The Seamsdress Sizing App & API Enhance your customer experience and reduce returns with Seamsdress. Our Shopify and Wix apps, along with our flexible API, let shoppers import their saved measurements, match them to your size charts, and get accurate fit recommendations right on your site. If tailoring is needed, they can instantly connect to a local provider through our national directory. It’s a seamless path from product to perfect fit—built to increase conversions and customer satisfaction.

With the Seamsdress Sizing App and API, customers can:

Fetch Body Measurements: Customers can securely retrieve their saved Seamsdress measurements in just one click.

Compare to Product Sizes: The app automatically compares body measurements to product size charts to recommend the best size—no guesswork.

Find a Local Tailor: If alterations are needed, customers can instantly connect to a local provider from the national Seamsdress Directory—tailors, designers, or manufacturers—for the perfect fit.

This AI-driven system also provides powerful insights for businesses. By analyzing aggregated, anonymized data on customer measurements, purchase history, and fit preferences, the platform can identify key industry trends. This includes identifying geographic "hot spots" of demand, audience demographics, and sizing needs, which helps brands make smarter decisions about what to produce, where to sell it, and how to market it. It also allows for more accurate demand forecasting, reducing overproduction and waste.

Why This Matters

Without skilled garment makers, reshoring will stall, and the U.S. risks losing not just jobs, but an entire heritage of craftsmanship. The future of U.S. garment production depends on more than trade policy; it depends on people. Seamsdress is building the infrastructure to find them, train them, and connect them to the brands that need them most. By ensuring that the artistry of garment making remains a viable, thriving career path and by modernizing the consumer experience with AI-powered sizing, Seamsdress is giving fashion brands the talent and technology they need to compete globally and build a more sustainable future.